DOWNHOLE SYSTEM

Reliable Drilling Solutions

Downhole System

Pulse Directional Technologies Inc. manufactures MWD and LWD systems that accurately place your customers in the payzone. With technologies like the ”Flashlight” at bit, ”Omega” resistivity, and ”Orbital” Azimuthal gamma you can confidently place the wellbore in the payzone.

PDT also manufactures other numerous MWD and LWD products that will assist in making your directional jobs operate smoothly and efficiently which ultimately saves you and your customers money.

Downhole Systems

PDT manufactures a variety of downhole products that allow our customers to perform top tier services. The tools are designed with your needs in mind which include top tier measurements engineered in a way that allows cost effective deployment.

Downhole Systems

PDT manufactures a variety of downhole products that allow our customers to perform top tier services. The tools are designed with your needs in mind which include top tier measurements engineered in a way that allows cost effective deployment.

''Flashlight'' Inclination and Gamma at the bit.

The Flashlight technology puts you in the drivers seat so that you can steer your wells from 1 foot rather than 50 feet back from the bit. With accurate Inclination, Azimuthal Gamma, Torque and Weight on bit measurements, this tool will take the guessing out of drilling any well. The Flashlight technology allows operators to drill a faster lateral with more useable wellbore. The At bit gamma and azimuthal gamma data lets you see the quality of the pay zone and make faster changes to the wellbore trajectory. When drilling in thin formation the tool allows formation top and bottom to be recognized much more quickly then conventional tools. The reaction time for course correction with conventional tools can be more than 80 feet of lateral which in a lot of wells can be too late. The “Flashlight’s“ close proximity to the bit provides the data for well corrections at the bit rather than calculated projections. The At bit inclination data gives immediate feedback when the slides are effective and save precious time. The directional driller can evaluate at a much faster rate then by conventional directional drilling, where the sensors are offset approximately 30-50 feet behind the bit.

''Omega'' Propagation Resistivity

With Omega resistivity you get all the benefits of a collar based resistivity logging tool without all the risk of losing it in the hole. With Omega resistivity, the probe based design allows it to be retrieved with the MWD tools and only leaving a slotted collar in the hole at a fraction of the cost of a collar based resistivity tool. Because of the Omega Resistivity’s innovative design, the cost of repair and service is more economical than traditional collar based resistivity tools. With Omega resistivity the tool automatically adjusts to different size collars, so one probe can be run in all the different collar sizes, reducing the cost of deployment. All Omega resistivity data is logged to memory and can be downloaded on surface to overlay with real-time data to make a high resolution memory log. Internal shock, vibration, tool diagnostics, raw phase and attenuation, and event status are logged to memory so post run data of the tool can be analyzed. Omega resistivity is a fully borehole compensated resistivity than can be run in oil based, water based and salt saturated muds. Omega resisitivity can been run with standard 3DMWD, legacy Tensor MWD and in Logging While Tripping (LWT) applications.

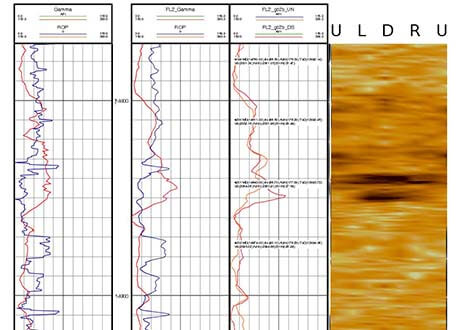

''Orbital'' Azimuthal Gamma Module

Pulse Directional Technologies is pleased to offer the Orbital Gamma Module which is designed to be incorporated with the MWD tool string. The Orbital Gamma replaces the existing MWD Gamma Module while providing 360 degree gamma, azimuthal gamma, Rotary Inclination and RPM. Increasing complexity of lithology requires more accurate decision making to remain in the pay zone. With Azimuthal gamma, operators can see the dip and direction of the formation and determine corrective course corrections real-time. By using the rotary inclination, operators can see true inclination while rotating between survey stations. The Orbital Gamma is capable of communicating to surface in real time, Azimuthal gamma measurements of 2, 4 or 8 bins, and storing up to 32 bins in memory. Using PDT’s surface decoder, an 8 bin Azimuthal gamma can be compressed into a single 16 bit word and decompressed on surface for blazing fast decoding.

Annulus Pressure While Drilling (APWD)

With the APWD tool, pressure measurements can be read real time to ensure the borehole stability before problems occurs. With a fully pressure and temperature calibrated device, accurate borehole pressure measurements can be used to calculate equivalent circulating density. These measurements can be used to improve drilling efficiency, perform formation integrity tests (FIT), avoid blowouts or getting stuck in the hole. The APWD tool is field programmable with adjustable sampling times for custom configurations. Annular pressure, FIT measurments, annular temperature, shock and vibration are just a few of the real-time measurements that can be sent to surface. The APWD tool can send up a total of 14 real-time measurements which are also logged to memory with system diagnostic and event data. The APWD is a fully retrievable tool that will seamlessly integrate to most legacy MWD systems.

''3D MWD'' System

3DMWD system is a platform that is able to support some of the most advanced technologies in directional drilling. It serves as a foundation of the Flashlight Gamma at bit, Omega Resistivity, APWD and Orbital Gamma tools. The system uses advanced encoding schemes that allow the data to be “packed up” and sent to surface at blazing speeds. Configuration software for the 3DMWD has been designed with the operator in mind. The configuration software has been built with drag and drop and pull down menus to reduce the chance of error. The 3DMWD system is a fully retrievable system that incorporates PDT’s short tool design that reduce failure prone interconnects for improved reliability. Key components like the pulser and surface equipment are compatible with legacy Tensor tools and can be used in your existing MWD kits.

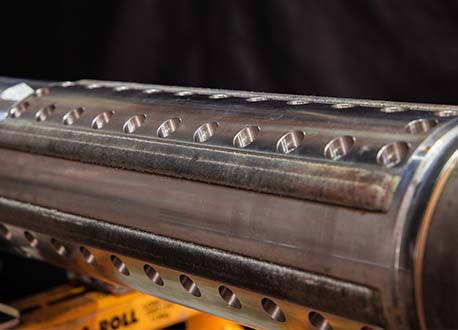

Gap Subs

At PDT we have been building Gap subs since 2006 and the product line has evolved to become one of the best gap subs for EMWD systems on the market. We pride ourselves in having a reliable and easily serviceable sub that can be customized to your own EMWD system and application. PDT has built gap subs that have replaced our competitors subs and have built custom subs that have been used in other oil field and mining operations. At PDT we can assure you that what ever the gap sub application we can build a product that will be more reliable and cost effective then our competition.